Spring Exterior Maintenance Guide for Multi-Site Facilities

From Winter Wear to Spring Readiness: Inspections and Maintenance for Post-Season Refreshes

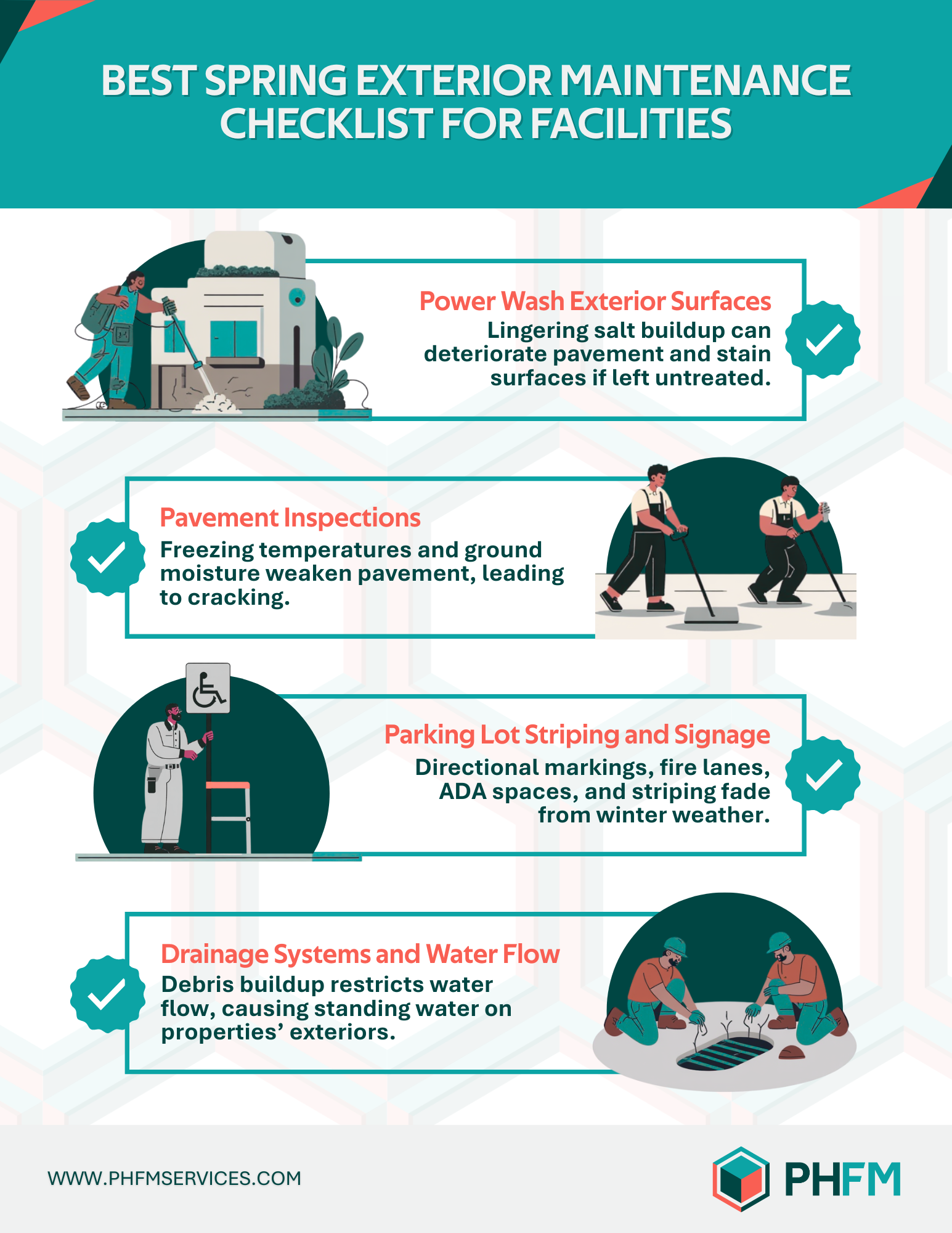

Cracked pavement, lingering salt residue, and pooling water around drains are proof of how tough winter can be on your properties’ exteriors. Trapped moisture and heavy de-icing materials take a toll on surfaces. As seasons shift to spring, full inspections of your locations are crucial in protecting assets and determining which areas require extra attention. Minor issues quickly escalate into structural concerns that disrupt operations and diminish curb appeal.

De-icing salts leave behind a powdery residue on exterior surfaces which leads to staining and pavement deterioration. This increases the chances of costly pavement repairs in the future. Addressing these effects promptly after the snow season jumpstarts routine, spring maintenance and landscaping practices.

Removing Salt Residue from Exterior Surfaces

Scheduling power washing services before spring rainfall helps remove salt remnants and prevent long-term surface damage. Common spaces to power wash include sidewalks and heavy traffic areas, along with building siding to maintain a clean, polished look for your brand.

Restoring your property with power washing boosts appearance while preparing surrounding surfaces for safer access and more efficient post-winter repairs.

Inspecting Pavement for Cracks and Potholes

Freezing temperatures and ground moisture bring weakened pavement, leading to new or widening cracks, uneven surfaces, and potholes. After the winter season, inspecting these areas and crack sealing pavement can prevent water intrusion and other materials from accumulating into the pavement structure. With quick action, distress and deterioration can be delayed.

Spring is the best time to fill pavement cracks to get ahead of the rainy season. Milder temperatures aid in the curing process, while more extreme temperatures don’t allow materials to adhere to surfaces properly.

Inspecting Parking Lot Striping and Signage

Parking lot signage and striping become dull during the winter months, causing poor visibility for guests accessing your properties and creating safety concerns.

Parking lot areas to inspect include:

- Directional Markings

- Fire Lanes

- ADA Spaces

- Parking Lot Striping

Faded lines and peeling paint are signs your parking lot needs an update. Depending on the amount of traffic your locations receive and local weather conditions, parking lot refreshes should be considered every 1-2 years to maintain curb appeal and promote parking lot flow for drivers.

Inspecting Drainage Systems and Water Flow

Debris buildup can restrict water flow, causing standing water in parking lots and landscaped areas that delay operations and other scheduled maintenance. Moisture then becomes a breeding ground for bacteria and pests on your exteriors. Monitoring drainage systems for early signs of damage or obstruction helps address problems before they escalate.

Inspections of drainage systems often include checking for cracks or broken grates caused by freeze-thaw cycles and displaced drain covers from snowplows or ice movement. Removing leaves and sediment buildup around drains will minimize the effects of standing water and prevent clogging. Documenting any abnormal findings and repairing quickly before spring rain begins reduces the risk of further complications in the future.

Spring Exterior Maintenance Checklist for Commercial Facilities:

Plan Inspections Early to Reduce Disruption

Spring provides a critical window for exterior inspections and maintenance to bring your properties back to full function after winter. The impact of freezing temperatures and heavy moisture becomes visible, and it's important to address issues before they worsen.

Scheduling early helps properties get ahead of seasonal demand and ensures faster turnaround to minimize disruptions in operations. PHFM provides seasonal inspections and maintenance to encourage long-term performance and asset protection with expert power washing services, parking lot maintenance, and drainage repairs.